Ventilation Systems

FINE BUBBLE MEMBRANE DIFFUSER

Repicky fine bubble membrane diffusers model RG-300, with thousands of micro holes, produce very high values of O2 transfer, making them ideal for installation in the aerobic reactors of effluent treatment plants, both industrial and cloacal (see chart O2 transfer)

Advantages

The main advantages of the system with blowers and air diffusers REPICKY, compared with superficial aerators are:

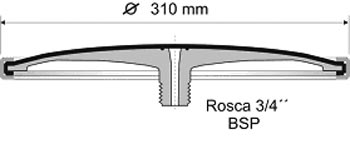

The air diffusers RG-300 can be installed in PVC or polypropylene grids and fixed with stainless steel brackets at the bottom of the reactors, or can be mounted on removable modules, single or multiple preassembled in the factory, reducing setup times and allowing their use in plants in operation with full reactors.

The use of these modules is also ideal for cameras with superficial aerators in operation where it is necessary to increase aeration, either permanently or for specific demands.

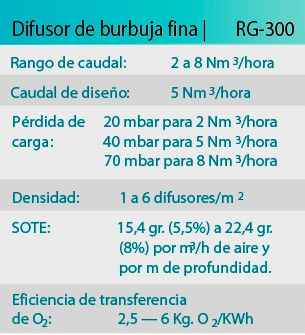

Main Technical Features

Standard materials: EPDM membrane or ACRYLICS Nitrile (other compounds on request), Base: ABS, External Aro: polypropylene.

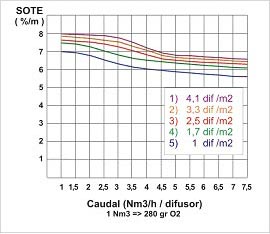

In large bioreactors, the required number of diffusers is determined by the total requirements of O2 as each diffuser provides a portion of the O2 required. The main variables involved in the transfer capability of each RG-300 diffuser are the useful depth of the reactor, the air flow rate per diffuser and the density or number of diffusers per m2 of reactor or chamber. In general, it has a better capacity to transfer O2 the deeper the chamber is, and the greater the number of diffusers per m2. In general, installations take between 1 and 2 m2 diffusers up to a practical 6 dif/m2 . For the initial calculations the design flow diffuser is used 5 m3 / h measured at 20 " C and normal atmospheric pressure (this condition is known as standard conditions). Then you may need an adjustment in the final amount of diffusers in terms of geometry and number of branches and grids adopted. The working range of the diffuser is 2 to 8 m3 / h, it is convenient to work at values close to the design flow as excellent results of aeration and mixing are obtained as well as long life of the membranes.

Oxygen transfer curve

Transfer of O2 per meter of depth depending on the air flow per diffuser (m3 / h) at 20"C, clean water and normal atmospheric pressure for various amounts of difusores/m2 |

Copyright © 2011 REPICKY S.A. . All rights reserved. |

Gral. Smith 76 - Bernal (B1883FKB) Buenos Aires - Argentina |

|

|

||